The Complete Guide to Industrial and Automotive Labels

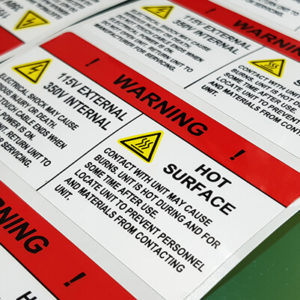

On the surface, industrial and automotive labels seem straightforward: A bright color, a basic symbol or some text, and you have what you need.

However, industrial and automotive labels, such as safety labels, serial number and asset tag labels, and automotive component labels, are deceptively complex. These aren’t fun stickers that are made primarily for aesthetic or promotional purposes. These labels can quite literally mean the difference between life and death. As such, they’re heavily regulated, and if not printed or applied to standard, can mean hefty fines for your organization.

To help you understand industrial and automotive labels a bit better, we’ve provided this guide, in which we’ll:

- Review the many design considerations you’ll need to think about when ordering these labels.

- Provide examples of industrial and automotive labels and a breakdown of their elements.

- Share what you’ll need to know placing an order with your custom label supplier.

Let’s dive in!

To jump to a specific section, click on one of the links below.

The Design of Industrial and Automotive Labels

When you’re ordering a typical product label, your designer has a considerable amount of room to exercise their creative chops. Barring some regulatory requirements, such as on food or medical products, the sky is virtually the limit when it comes to shape, color, font, and graphics.

Industrial and automotive labels are very different. In many cases, such as with safety labels, chemical labels, or automotive labels, there are strict regulatory requirements that dictate the label’s design.

Here is an overview of these standards in the United States. If you manufacture or distribute products in other countries, note that different regulatory requirements may apply.

Safety Labels

Safety labels are subject to the ANSIZ535 series of American National Standards. Three out of the six standards apply to labels:

Safety Colors

Safety Colors

ANSI Z535.1 sets the standard for each of the safety colors: red, orange, yellow, green, blue, purple, white, brown, gray, and black. It also describes each color’s ink formulation and closest PANTONE® color, as well as safety color tolerances illustrating acceptable ranges in hue, value (lightness), and chroma (saturation), among other regulations.

Safety Symbols

ANSI Z535.3-2011(R2017) sets the standard for the design, evaluation, and use of safety symbols which identify and warn against specific hazards and provide information to help avoid personal injury. These standards ensure that safety symbols are uniform and applied in a universally consistent manner, so as to avoid any confusion or misinterpretation.

Product Safety Signs and Labels

ANSI Z535.3-2011(R2017) outlines requirements for the design, application, use and placement of safety signs and labels, covering such topics as signal word panels (e.g., DANGER, WARNING, CAUTION), lettering size and style, sign and label placement, and maintenance. The purpose of this standard is to ensure safety labels are consistent and uniform.

Why is uniformity and consistency so important in safety labels? It’s because again, these labels can mean the difference between life and death. Without these standards, Company A might choose red labels for danger labels while Company B might choose yellow – and if an employee leaves Company A for Company B, they might end up misinterpreting their new employer’s warning labels, perhaps with tragic results. By implementing universal national standards, there is far less risk that these labels will be misinterpreted.

Additionally, uniformity of industrial labeling makes it much easier when plant supervisors are conducting safety walkthroughs or when regulatory body representatives perform audits – everybody is looking for the same thing, every time.

Chemical Labels

Chemical labelling is subject to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). Managed by the United Nations, it establishes universal global standards for universal warning pictograms and safety data sheets.

The U.S. adopted the GHS in March of 2012 under OSHA, making these standards part of federal regulatory requirements.

The standard label elements included in the GHS are:

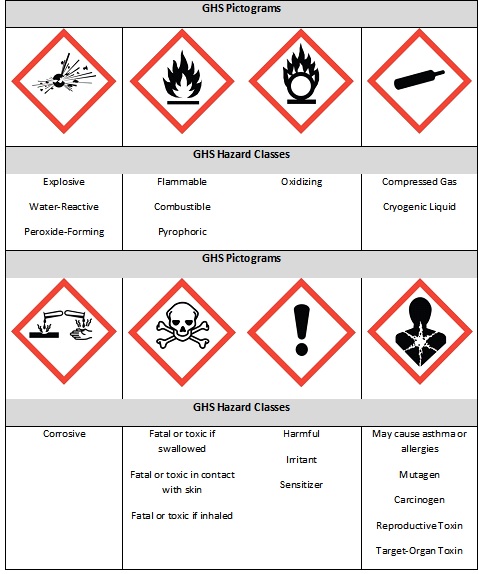

- GHS hazard pictograms: These communicate physical, environmental, and health hazard information, and are assigned a hazard class and category.

- A signal word: The signal word, such as “Danger,” or “Warning” indicates the severity level of the hazard

- A GHS hazard statement: These are standardized phrases assigned to the hazard class in question that describe the hazard in a consistent and accurate manner.

An example would be the easily recognizable skull and crossbones pictogram indicating acute toxicity. If the signal word is “Danger,” the hazard statement would either be “Fatal if swallowed” or “Toxic if swallowed.” If the signal word is “Warning,” the hazard statement would be “Harmful if swallowed.”

Below are some other examples of pictograms and hazard classes.

Automotive Labels

Auto manufacturers not only have to ensure they have proper safety labeling at their plant, they also have to keep abreast of automotive labeling standards. In 1984, in response to mass inefficiencies created by a lack of standardization, the AIAG (Automotive Industry Action Group) established a set of standards for the industry.

Auto manufacturers not only have to ensure they have proper safety labeling at their plant, they also have to keep abreast of automotive labeling standards. In 1984, in response to mass inefficiencies created by a lack of standardization, the AIAG (Automotive Industry Action Group) established a set of standards for the industry.

These standards set specifications for items such as:

- Bar code height

- Quiet zones around bar codes

- Text dimensions

- Symbol placement and height

- Label height and width

- Label durability

- Label placement and orientation

Rationale is also provided for many of these standards. For example, bar code labels are always to be white, with black print. Why? First, it’s less expensive. Second, the process can be broken too easily by supply constraints (if your label supplier ever runs out of black ink, something is very, very wrong). Third, the high contrast between black and white provides optimal results when using scanning technology. One more surprising reason? Approximately 10% of the male population has some form of colorblindness, making a plain, high-contrast label a must.

Other Industrial Labels

Other industrial labels, like tool labels, inspection labels, or instructional/direction labels may not be subject to the same stringent regulations, but there are still some best practices that should be followed:

- Make sure the label contains as much information as it needs to, in the clearest language possible.

- Make sure your label’s text is crisp, has good contrast, and can be easily read at a use-case distance (e.g. if the label will be above a door, make sure it’s legible from several feet away).

- Never apply a label in a way that will interfere with the operation of machinery or equipment.

- For better label life, remove oils, dirt, and sediment from the application surface first.

- If a label will be used outdoors, try to apply it in a place where it will not receive direct sunlight or exposure to weather.

- Because industrial labels need to be durable, paper label stock is rarely a good choice (the folks at Industrial Hygiene News are in full agreement on this). Polypropylene labels — especially BOPP (biaxially-oriented polypropylene) labels — are a much better choice, with their high resistance to temperature fluctuations, abrasion, and wet conditions. For additional durability, labels can be covered with an abrasion and/or UV-resistant coating.

What About Language?

Considering the importance of industrial and automotive labels, it’s vital to think about who will actually be reading the label. Symbols are a critically important aspect to safety labels, for example, particularly if the people viewing the labels speak a different language.

ANSI has covered this topic in ANSI Z535.4:

“If it is determined that additional languages are desired on a safety sign, the following formats should be considered. In all examples, the use of symbols is strongly encouraged in order to better communicate the sign’s hazard information across language barriers.”

Does ANSI say which foreign language to use? No. That decision belongs to the facility owner/manufacturer. Depending on where your facility is located, Spanish may be a dominant second language at your plant. Or it may be Arabic, or Mandarin, or any other language or languages. If you have multiple locations across the country (or continent), you may need multiple batches of labels with different languages, to ensure your facility employees and visitors have the clear information they need to stay safe.

Ordering Industrial/Automotive Labels

Attractive stickers can be obtained just about anywhere, but when it comes to getting durable, high-performing, and compliant industrial and automotive labels, it’s vital to choose a reputable and experienced custom label supplier.

When ordering industrial and automotive labels, your label supplier should ask you about:

Application Surface

Adhesives bond in different ways to different surfaces and can also be affected by any residue or treatments that are on that surface.

Very few industrial settings are perfectly clean and dry. When ordering, it’s vital to give your custom label supplier as much information as possible about the application surfaces. That way, they can help you get the longest-lasting label possible for your budget by:

- Selecting an adhesive that will work well in your industrial setting.

- Giving you helpful information on how to properly prep the surface before applying your labels.

Otherwise, you may run the risk of having to replace all your labels in an alarmingly short period of time, costing you money and time.

The Label Environment

Besides the application surface, your custom label supplier needs to know what conditions your label will face. Is your warehouse refrigerated? Will the label be applied to a piece of equipment that is regularly exposed to water and solvents? Is the label for outdoor use, where it will be exposed to sunlight, fluctuating temperatures, and possible harsh weather conditions? The more details you can provide to your label supplier, the better your label will weather anything your plant can throw at it.

Application Method

Perhaps your labels will be applied by hand. Or, in some manufacturing environments, the labels may be machine-applied. This is information that your label supplier will need to know, to ensure your labels arrive in an appropriate format, whether it’s in rolls, sheets, or single labels.

Volume and Supply Chain

Storage space costs money. But volume pricing is often a better deal if your usage will justify it. An experienced custom label supplier will talk to you about your anticipated volume needs and may be able to offer “just-in-time” production methods that support lean manufacturing programs, keeping you from having to store an extraneous amount of labels in your warehouse.

Getting an industrial or automotive label that looks great and performs perfectly is not necessarily a complex task, but it is one that requires time, consideration, and expertise.

Visit our portfolio to learn more about our industrial and automotive labels or contact us today if you wish to order applicable samples.