Eco-Friendly Labels: For a Healthier Planet and a Stronger Brand

How to Make Sustainable Label Choices to Appeal to Modern Consumers

A rapid and seismic shift is underway in how companies view their roles in preserving the environment. Sustainability is going mainstream as corporations begin to define their environmental values, adopt green initiatives, and even commit to zero waste.

Just a few years ago, many of these same businesses would have claimed it was impractical and unprofitable to concern themselves with conservation.

What’s changed?

The growing environmental awareness of the business world is, in part, driven by changing attitudes among the population at large. Companies, after all, are made up of people, and people throughout American society are beginning to look for ways to help preserve our natural environment and stave off a global ecological and climate crisis. In fact, according to a 2019 Consumer Brands Association report, 74% of adults are concerned about the environment in the United States. Among millennials that percentage rises to 82%.

But there’s also a business case to be made for going green. Put simply, it’s what consumers want, and they’re willing to pay more for it.

For a 2020 report, the Capgemini Research Institute surveyed 7,500 consumers globally. Researchers found that:

- 79% of consumers are changing their preferences based on social responsibility, inclusiveness, or environmental impact.

- 64% of consumers say buying from sustainable brands makes them feel happy about their purchases.

The COVID-19 pandemic seems to have focused consumers’ attention on the importance of sustainability. According to the Capgemini study, 67% of consumers said the crisis has made them more cautious about the scarcity of natural resources.

64% of consumers say buying from sustainable brands makes them feel happy about their purchases.

Nearly three out of four millennials say they would pay more for sustainable products.

As would be expected, the environmental imperative is stronger among younger generations. Nearly three out of four millennials say they would pay more for sustainable products (according to Nielsen). But it’s worth recognizing that over half of baby boomers say they feel the same way.

Table of Contents

Consumers Want Eco-Friendly Labels

Consumers are attracted to brands that demonstrate environmental friendliness and a strong commitment toward sustainability, but it’s not always clear what those terms mean to consumers. Sustainability can refer to the energy it takes to manufacture and transport a product, the renewability of the resources used to make a product, the pollution and waste generated by a product, and/or the impact of a product on local communities and ecosystems.

All of these sustainability factors intersect with product packaging. A recent GlobalWebIndex survey asked consumers what they wanted from environmentally friendly packaging. Here’s what they said:

- 64% want recyclable packaging.

- 53% want reusable packaging.

- 46% want to reduce overpackaging.

- 39% want compostable or biodegradable packaging.

- 36% want packaging made from renewable resources.

- 35% want it to be easier to separate packaging materials for disposal.

The market is taking notice. The global sustainable packaging market will exceed $400 billion in less than a decade, growing by 7.7% each year.

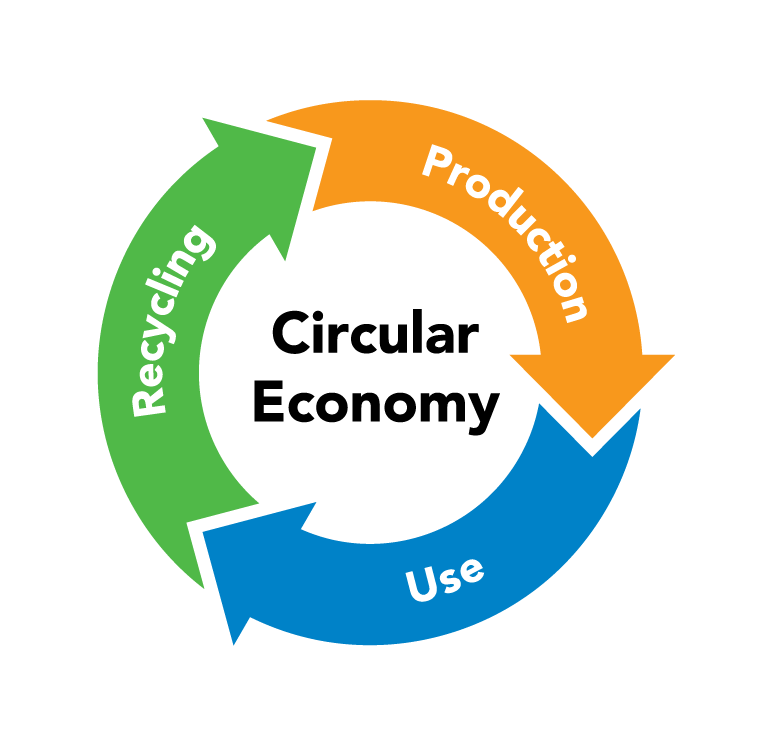

The Circular Economy: Looking Beyond Recycling

One way to think about the sustainability of your product packaging is in terms of a closed loop.

For the most part, the world economy is linear. We extract resources, convert them to products, people buy the products, and eventually, people discard the products. Most of what we buy ends up in the trash, and relatively quickly.

Sustainability advocates call instead for a circular economy. In the circular economic model, waste and pollution are designed out of the system, products and materials are kept in use, and natural systems are allowed to regenerate.

Companies interested in reducing the environmental impact of their product packaging should not overlook the many ways product labels can help create this circular economy.

Product labels may seem like a small part of the picture compared to the sheer bulk of boxes, bags, and bottles. But as this paper will demonstrate, labels contribute significantly to the overall environmental footprint of a product throughout its lifecycle, from manufacture to disposal (and ideally, reuse in one form or another).

Product labels, then, represent an opportunity for companies to make choices that align with their environmental values and sustainability goals – and those of their customers.

Labels contribute significantly to the overall environmental footprint of a product throughout its lifecycle, from manufacture to disposal (and ideally, reuse in one form or another).

It’s important to remember that when it comes to product labels, true sustainability goes well beyond making sure your labels are recyclable. As with any manufactured object, a product label is the end-result of a process of design, sourcing, production, storage, and distribution. Each step along the way can have a positive or negative environmental impact depending on the choices you make.

Products labels also carry messages, and therefore offer unique opportunities to influence your customers’ sustainability practices.

A fundamental principle in the environmental movement is that everything is an element of a greater whole. A minuscule label has its place in a chain of interconnectivity that includes the entire planet. And so, we hope this page will help you think about sustainability and product labels in a holistic sense.

In the following sections, we’ll discuss how, by making eco-friendly decisions about your product labels, your company can use more sustainable resources, reduce waste, encourage your customers to reuse packaging, and – yes – promote and participate in recycling.

Preserving Forests with Sustainable Product Labels

Forests aren’t just nice places to take a hike. Forests absorb carbon, keeping greenhouse gases that contribute to climate change out of the atmosphere. They host a considerable portion of the world’s biodiversity – including many plant and animal species that remain undiscovered.

Human communities need forests, too, relying on them for food, energy, and water. Three-quarters of the planet’s accessible freshwater comes from forested watersheds, according to a U.N. report.

Between 1990 and 2016, the world lost more than half a million square miles of forest, and deforestation is continuing today at alarming rates. The main culprit is agriculture, but the paper industry is also a significant contributor to deforestation. The paper and pulp industry uses over 40% of all industrial wood traded globally.

Paper is one of the most common label materials, so by choosing to use more sustainable alternatives, you can help keep our forests alive and nurturing life on our planet.

FSC-Certified Labels

We may never eliminate the countless functions paper serves in human life. But we have learned that it’s possible to harvest trees to make paper without devastating our precious forests. That is the objective of the Forest Stewardship Council (FSC).

The FSC is a non-profit international organization founded in 1993 to promote responsible forest management. The FSC created a set of standards for sustainable forestry. The organization certifies products that “come from responsibly managed forests that provide environmental, social and economic benefits.”

For paper products, FSC certification covers the entire chain of custody, from the forest, to the paper manufacturer, to the paper merchant. If a label vendor’s products are FSC certified, it means they, too, have gone through the rigorous process of demonstrating the sustainability of their raw materials and supply chain.

Tree-Free Labels

Paper-like products can be manufactured without trees. Tree-free label stock can be made from bamboo, hemp, sugarcane, and cotton. “Stone paper,” made mostly from calcium carbonate, doesn’t come from plants at all — although it does include a little bit of plastic.

Whenever possible, choose thinner label materials. The less material your label is made from, the fewer resources it will consume.

Reduce Waste for Eco-Friendly Labels

Often, the most sustainable choice you can make is not about the type of material you use but the amount. In matters of sustainability, less is more. The less paper, film, ink, and adhesive needed to create your product label, the less your label’s environmental impact will be.

Here are a few opportunities to conserve resources with the design and construction of your product label:

The less paper, film, ink, and adhesive needed to create your product label, the less your label’s environmental impact will be.

Reduce VOCs

Among the most significant environmental concerns in the printing industry is the presence of volatile organic compounds (VOCs) in ink. Volatile organic compounds are toxic carbon-based chemicals that can be released into the air during the production and application of certain inks. VOCs are pollutants; they contribute to the creation of ozone and smog and, in high concentrations, may have adverse health effects. (Note: VOCs are present in many cleaning products, paints, and fuels, as well as ink.)

Conventional petroleum- and solvent-based ink can contain high levels of VOCs – 20% to 40% for some inks. Water-based ink has much lower VOC levels, typically around 3% to 5%.

The lowest VOC levels are found in UV inks. Unlike solvent- and water-based inks, UV inks do not dry in the air. They solidify upon exposure to UV radiation, therefore releasing very little in the form of evaporated gas. UV inks can contain VOC levels of less than 1%.

Sustainability Tip:

The various types of ink behave differently when applied to different surfaces and when exposed to different environments. VOC levels should certainly be a consideration when choosing ink, but be sure to talk to your label printer about how you plan to use your custom label as well. An expert label printer will guide you toward the right ink for your application and your environmental goals.

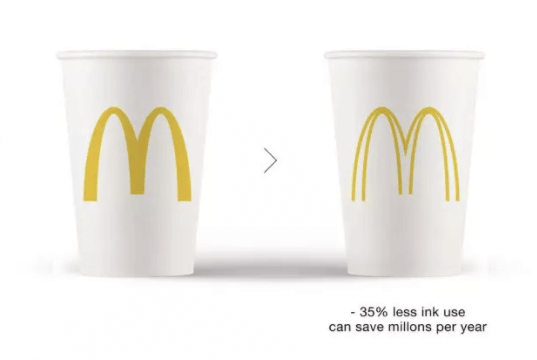

Scale Down Labels – Design for Sustainability

A growing movement in the graphic design world encourages designers to think about how their creative decisions add to or subtract from the overall sustainability of their creations. This approach is called sustainable graphic design.

You might be surprised to find that a few minor visual tweaks can decrease your label’s environmental footprint significantly.

One simple first step may be to shrink the size of your label. Ask yourself how large your label really needs to be to get its job done (standing out on crowded store shelves, for instance). Once you hit that sizing sweet spot, anything bigger is waste.

Could you choose smaller fonts? Smaller letters use less ink, but they’re also harder to read. In this case, it’s important to balance legibility with conservation. Your label printer can help you weigh the pros and cons.

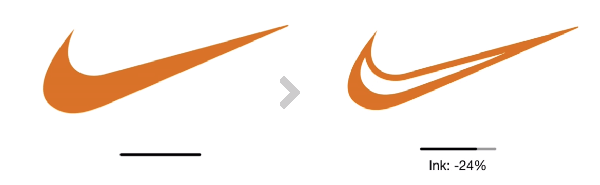

Your logo design may represent another opportunity to reduce your use of ink and energy. In 2017, a French designer demonstrated that iconic brands such as Nike and McDonalds could consume between 20% and 40% less ink simply by “hollowing out” their logos. For the most part, the designer managed to transform these logos into more eco-friendly versions without losing their instant recognizability.

You might be surprised to find that a few minor visual tweaks can decrease your label’s environmental footprint significantly.

Streamline the Liners

Whether they’re shipped in rolls or stacks, pressure-sensitive labels typically come on protective liners. The liner has no purpose once the label has been peeled off, leaving the liner material destined for the landfill.

Liners are made from low-grade paper coated with a release agent – such as silicone – and are recyclable, but not in the standard paper recycling stream. Some recyclers have discovered ways to remove the release agent from liners.

Another popular – and eco-friendly – trend is to simply make the liners thinner. Lightweight liners use less energy to manufacture, use fewer raw materials, and reduce freight costs and packaging waste. Plus, thinner liners mean more labels fit on a single roll, reducing change-over time and increasing productivity.

Even non-recyclable liners can still be made using recycled materials, meaning they consume fewer natural resources to produce.

Linerless labels are also available from some label suppliers. Linerless labels are coated directly with a release agent. In a roll of linerless labels, the label below a label behaves like a liner. An advantage of linerless labels is that they take up less space and weigh less per roll than conventional labels.

Sustainability Tip:

Your label printer may offer a program to collect your used liners and ship them to a specialized recycler.

Look Into PLA Labels

Polylactic acid (PLA) is a biodegradable polyester derived from renewable sources such as corn starch. PLA looks and behaves like petroleum-based plastic (it might be referred to as a “bioplastic”), but when exposed to the elements, it biodegrades in a matter of months. In other words, PLA labels are compostable.

From a sustainability standpoint, PLA is a promising material, but experts are still working to determine whether its benefits outweigh its drawbacks. One downside of PLA is that, although it degrades much faster than petroleum-based plastic, it does consume agricultural resources, diverting them from food production and promoting the use of chemical fertilizers.

Consider Compostable Labels and Packaging

Composting serves a crucial function in the circular economy. The composting process breaks down organic waste, turning it into a useful, natural product that nourishes the soil and helps the next generation of crops grow.

Once favored mostly by home gardeners and farmers, composting is rapidly growing in popularity. Many cities and towns now offer curbside composting services. According to the Environmental Protection Agency, 2.6 million tons of food waste were composted in the U.S. in 2018, compared to 680,000 tons in 2000.

Food isn’t the only thing that can be composted. Packaging designers have been experimenting in recent years with compostable containers made from biodegradable resources such as cornstarch, mushroom roots, and seaweed.

Product labels can also be made from compostable materials – including paper. However, non-organic material must be kept out of the compost heap, so the adhesive must also be biodegradable. Otherwise, if you want to help your customers compost your product packaging, make sure your labels come off cleanly, leaving no adhesive residue behind.

Encourage Reuse or Repurposing of Product Packaging

If you’re old enough to have grown up before recycling became widespread, you might remember converting coffee cans into piggybanks and using margarine containers to store odds and ends. To this day, many of us still store important documents and precious photographs in shoeboxes that date back to the previous century.

The reuse of product packaging has a long and productive history. But these days, when we think about sustainable packaging, we often skip past reuse and go straight to recycling.

Compared to the landfill, recycling is a more environmentally beneficial fate for product packaging. But it takes a lot of energy to melt down plastics and shred and reconstitute paper. The recycling process can also release pollutants into the air and water.

On the other hand, there is almost no ecological downside to reuse.

Reuse and repurposing are critical practices in the circular economy as they extend the life of products and packaging or give them new lives altogether.

When we think about sustainable packaging, we often skip past reuse and go straight to recycling.

How Your Product Labels Can Promote Reuse and Repurposing

People are always coming up with clever new ways to reuse their product packaging. We’ve seen milk cartons become birdfeeders, cosmetic containers become vases, and cereal boxes become musical instruments for kids.

Some people are more creative than others, however. Your customers might need a bit of inspiration on how to reuse your product packaging. This is where your label comes in.

You can use your product label to teach your customers about the environmental and money-saving advantages of reuse. Your label can showcase ideas for repurposing and encourage customers to share their suggestions on social media – a great way to spread the word about your commitment to sustainability. Custom URLs, barcodes, and NFC tags embedded in your labels can direct your customers to websites where they can get more information about reusing your product packaging.

Be sure your label doesn’t get in the way of repurposing. A glass jar can make an attractive beer mug, but not if it’s permanently covered with sticky residue. If reuse is a priority for your brand, work with your label printer to create a label that removes easily and leaves no traces.

One such option is a dissolvable label, which disintegrates in seconds (along with the adhesive) when washed with water. Dissolvable labels quickly convert product packaging into reusable storage containers.

If reuse is a priority for your brand, work with your label printer to create a label that removes easily and leaves no traces.

Recycling Your Custom Labels

Choose Adhesives Designed for Recycling

When it comes to the recyclability of labels, the challenge lies not in the label material, but the adhesive. Most conventional adhesives can’t be recycled.

In most communities, it’s no longer necessary to remove labels from glass, plastic, and metal containers for recycling. The recycling process burns away labels and adhesive.

However, even a small amount of adhesive can contaminate certain substances – like clear plastic – during the recycling process. Adhesive residue can cloud the appearance of clear plastic, rendering it less desirable for reuse.

To address this problem, some manufacturers have formulated adhesives that are designed to be washed off. Avery Dennison, a major supplier to custom label printers, calls its solution CleanFlake Adhesive Technology. CleanFlake was developed to improve the recyclability of polyethylene terephthalate (PET) bottles, 560 million of which are wasted every year due to incompatible label materials.

Should Your Labels Be Removable?

You might remember having to remove labels before recycling bottles and cans. But these days, most recycling facilities can handle labels without difficulty. This is a good thing! It eliminates a hassle from recycling (so more people will do it).

There are still some great reasons to make your labels easy to remove, however:

- You market your products in an area that hasn’t caught up with modern recycling practices. In a few places, people are still peeling labels.

- You want to encourage your customers to reuse product packaging. Unless your label has a cool design or beautiful appearance, few people will want to upcycle a product with the label still attached. In this case, you may want to consider using a washable or dissolvable label.

- The labels themselves are recyclable. Paper labels can be recycled as long as they’re not contaminated by food or the wrong kind of adhesive (see main text).

- The labels themselves are NOT recyclable. Some dense plastics, such as PVC, can interfere with the recycling process.

- The labels are (or may one day become) collector’s items. People do collect product labels – especially for limited-edition or rare items.

Can Labels Be Recycled?

Synthetic labels cannot typically be recycled. Paper labels can – but only if they’re not contaminated by adhesives.

The paper recycling process uses water to transform paper back into pulp, but conventional adhesives will not dissolve in water. Instead, the adhesive will break down into small particles that can lodge into papermaking equipment, damaging both the equipment and the finished product. These tiny impurities – called “stickies” – cost the paper industry hundreds of millions of dollars per year, according to some estimates.

To combat the scourge of stickies, the U.S. Postal Service led an effort to create recycling-compatible adhesives (RCAs). Recycling-compatible adhesives do not break down in water but remain large enough to be sifted out of the pulp. The USPS now uses RCAs exclusively in its postage stamps.

If RCAs are not practical, another way to make paper labels more recyclable is to simply use less adhesive and only on the areas that are critical for holding the label onto the product – such as the edges of a paper loop surrounding a glass bottle. This way, environmentally conscious consumers can cut away the adhesive and recycle the rest of the label.

The paper recycling process uses water to transform paper back into pulp, but conventional adhesives will not dissolve in water. Instead, the adhesive will break down into small particles that can lodge into papermaking equipment, damaging both the equipment and the finished product.

Making Labels From Recycled Materials

Unfortunately, most of the product labels currently in circulation will not be recycled. But your brand can still contribute to the circular economy by choosing to use recycled materials to create your custom labels.

Recycling is far better for the environment than landfills or incineration. For example, according to the EPA:

- Producing recycled paper consumes about 40% less energy than making paper from virgin wood.

- Preventing one ton of paper waste saves up to 17 mature trees.

- Making plastic from recycled material requires about a third less energy than producing plastic from raw materials.

Ask your label printer about the possibility of crafting your label from recycled materials. However, keep in mind that recycled materials may look and feel different from virgin raw materials.

How to Shrink Your Label

Smaller labels use less material, ink, and adhesive, and therefore, are more sustainable than their larger counterparts. Smaller labels also require less storage space and burn less fuel in transport. How can you help your product label shed a few square inches?

- Follow the minimalist design trend. Minimalism is in right now, especially among high-end brands whose customers appreciate understated elegance. Just be aware there’s a fine line between minimalist and boring. (Here are a few brands that do minimalist right.)

- Exploit the digital space. While label real estate is limited, the online world offers boundless possibilities. Direct your buyers to more information online (such as ingredients, recipes, and your brand’s story) using simplified URLs, QR codes, or NFC chips.

- Expand into the third dimension. Foldable labels (referred to in the business as extended content labels) won’t reduce your use of materials. But they do require less adhesive, making your packaging easier to recycle. You can also choose to package booklets and inserts with your products; these don’t require any adhesive at all.

As you consider shrinking your product label, keep in mind that in the eyes of regulators, some information is non-negotiable. Pharmaceutical products must include an FDA-mandated drug facts label, for example. Electronics must include compliance symbols like the FCC non-interference mark.

Your label printer can help you determine the most effective way to minimize your label while remaining compliant with federal and state regulations.

Work with Eco-Friendly Label Printers

s global awareness of environmental issues spreads, companies in every industry are looking for ways to become more efficient, to use fewer raw materials and less energy, and to practice good stewardship of natural resources. The label printing industry is no exception.

Eco-conscious label printers reduce their environmental footprints – and therefore, the footprints of their customers – by:

- Shipping labels in smaller, lighter packaging.

- Consolidating print runs to reduce waste. (Most waste is generated during the setup process.)

- Partnering with environmentally friendly suppliers.

- Switching to energy-efficient lighting.

- Monitoring and controlling heating and air conditioning to minimize energy use.

- Assembling a sustainability team or designating a sustainability point-person to spearhead company-wide green efforts and look for new ways to reduce waste.

Sustainability Tip:

Look for third-party indicators that demonstrate the environmental commitment of your label printing partners. Widely recognized third-party indicators include:

- L.I.F.E (Label Initiative for the Environment) certification. The Tag and Label Manufacturers Institute (TLMI) awards L.I.F.E. certification to member companies that have demonstrated good environmental stewardship.

- Sustainable Green Printing (SGP) Partnership certification. SGP certification was developed by the printing industry to “define what it means to be a sustainable printer and to offer credible validation by a third party."

- ISO 14001 certification. ISO 14001 is an international standard for designing a framework that allows organizations to set up effective environmental management systems.

Sustainability at The Label Printers

At The Label Printers, we feel it is our responsibility as a company to be a good corporate citizen, and that includes being a good steward of our environment. Sustainability is a consideration in all that we do.

“It’s important to work with companies who are doing what they can to minimize their own impact, and who are figuring out how to reduce their environmental footprint without sacrificing quality or performance. We encourage people to reduce, reuse, and recycle wherever possible, both in their personal environment and at their business. Every bit helps.”

– Lori Campbell, President, The Label Printers

“We can all do our own individual part,” adds George Tommasi, VP of Human Resources and leader of The Label Printers’ Sustainability Team. “A component of that is being aware of the many programs out there that can help your business reduce waste and recycle your materials. As much as possible, we should reduce the waste that we generate, reuse what we can, and recycle the rest.”

Our efforts to reduce the environmental impact of our operations include:

(Learn more about our Environmental Responsibility and Corporate Citizenship philosophies.)

Not only is it possible to produce a quality product in an environmentally sustainable way, it’s smart business. At The Label Printers, we’re happy to do our small part in helping our customers reduce their environmental footprint and work toward a cleaner, healthier planet.

Want to learn more? Click here to contact us today.