The Complete Guide to Electrical and Electronics Labeling

Electrical equipment and components are all about precision. Every element must be engineered and fitted together to exacting specifications to perform safely and satisfactorily. The details matter.

The details matter to us, too. At The Label Printers, we understand that electrical and electronics labeling isn’t just for decoration. Electronics labels have jobs to do: safeguarding people, protecting the environment, instructing users, and complying with regulations – among many other things.

This is why you can trust us with your labeling needs. We care about getting the little things right – and the big things, too – just as much as you do.

Here is some information that our electrical and electronics labeling clients (and future clients) should find helpful.

To jump to a specific section, click on one of the links below.

Using Labels for Security Tracking and Asset Management

Electrical products are often constructed from a dizzying array of components, each manufactured and sourced along a complex supply chain that spans the globe. A major concern is that electrical products – especially consumer products, such as smartphones, smartwatches, tablets, and audio/visual equipment – are among the most sought-after items on the gray market.

As a manufacturer of electronics or electrical components, you require a holistic view of your supply chain to ensure:

- All your components originate from trusted suppliers.

- Your supply chain is functioning efficiently.

- Your retailers and customers are receiving genuine items.

- Your products are not being redirected to the gray market.

The answer to these threats against your brand’s reputation and revenue is track and trace technology.

What Is Track and Trace?

Track and trace is the common name for systems designed to protect brands and secure their supply chains.

Tracking is a process or technology that allows companies to follow and record the flow of components and products throughout the supply chain. Tracing involves using the data collected in tracking to trace an item found in commerce back to its source.

Track and trace systems typically capture data concerning:

- What items have been shipped.

- How the items were shipped.

- What ports the items went through.

- Whether or not the items reached their final destinations.

Track and trace systems comprise multiple elements and data sources. For example, if you’ve ever registered a product online, you most likely contributed data to a track and trace program.

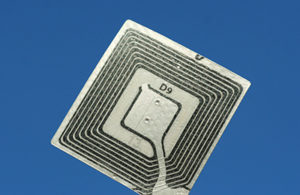

From a labeling standpoint, the two most common technologies used in track and trace systems are barcodes and radio-frequency identification (RFID) tags. Both are methods for encoding information that can be used to identify and track products down to the individual item.

Barcodes are one- or two-dimensional patterns meant to be read with specialized laser scanners or optical readers. Depending on its complexity, a barcode can contain thousands of bits of data – even more when linked to a writable database.

Radio-frequency identification (RFID) uses electromagnetic fields to read information stored on tiny transponder chips, sometimes as small as the head of a pin. These chips are paired with RFID antennas, which typically are much larger. One advantage of RFID tags is that they can be read in bulk and at a distance (while barcode readers need a direct line of sight to the barcode).

Track and trace technology may seem complicated and costly, but today, a variety of specialized systems of varying degrees of sophistication are available for helping electronics brands monitor their supply chains effectively. At the Label Printers, we have the expertise and experience in brand protection to help you find affordable, practical solutions to secure your reputation and revenue stream.

Labels and Electronics Recycling

For the most part, you can’t just drop an electronic item into a conventional recycling bin. While electronics are made from plastic, metal, and glass – all resources which can see a new life after being recycled – they may also contain materials that can be hazardous to human health and the environment.

E-waste is piling up in landfills around the globe, leaching dangerous substances into the environment. A United Nations report predicts that

But alongside this troubling trend comes a promising one. More and more brands are starting to take their responsibility seriously to protect and preserve the environment and the well-being of their communities.

The makers of electronics can contribute to the green movement by helping their customers find safe ways to recycle their products when they are finished with them. Labels play a crucial role in keeping electronics out of landfills. Labels can remind consumers to recycle or donate, direct people to the proper outlets for recycling electronics, and alert recycling facilities to the presence of toxic materials.

A good electronics recycling label:

- Gives clear instructions in a legible font.

- Uses symbols and imagery that are easily decipherable, with colors that stand out.

- Is placed in a location where consumers and recycling personnel can’t miss it.

- Is durable enough to last the lifetime of the product.

At the Label Printers, we believe we have an obligation to current and future generations to do what we can to reduce our ecological impact and to be good stewards of environmental resources. We are committed to reducing, reusing, and recycling whenever possible, and strive toward a zero-waste printing process.

We would love to help you and your company achieve your environmental goals, as well. Contact us to discuss your needs for electronics recycling labels.

Electronics Labels and Compliance

Labels are sometimes required by law and industry regulations, generally to provide an environmental or safety warning. In these cases, it’s not just what the labels say that matters, but how they’re formatted. Electronics companies that fail to abide by label regulations risk fines, lawsuits, and users’ health and safety.

Regardless of the specific regulatory requirement, compliance labels should be durable, able to withstand time, rough handling, adverse environmental conditions, and caustic solvents without peeling, tearing, or smudging.

Here are some of the most significant label-related regulations of which makers of electronics and electrical components should be aware:

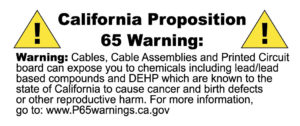

California Proposition 65

In 1986, California passed the Safe Drinking Water and Toxic Enforcement Act, a ballot initiative aimed at protecting the state’s drinking water from contamination. Commonly known as Proposition 65, the regulation says that products sold in California must indicate if they contain chemicals that have been known to cause cancer or birth defects.

As of January 2020, California’s list of potential carcinogens included over 1,000 substances.

Proposition 65 isn’t just a concern for companies based in California. Any business that sells products in California must comply. This is why Proposition 65 warning labels are common outside of the Golden State. Few manufacturers want to miss out on the opportunity to sell to residents of America’s most populous state.

Prior to 2016, Proposition 65 warning labels merely had to say, “WARNING: This product contains a chemical known to the State of California to cause cancer.” But in August 2016, California expanded the law to require more specific information.

According to Proposition 65, warning labels must include:

- The name of at least one listed chemical that prompted the warning.

- The URL for the website p65Warnings.ca.gov, where consumers can get more information on the health effects of listed chemicals.

- A triangular yellow warning symbol.

The following example is from California’s informational website about Proposition 65:

WARNING: This product can expose you to chemicals including [name of one or more chemicals], which is [are] known to the State of California to cause cancer. For more information go to P65Warnings.ca.gov.

If you are unsure whether your electronic product or electrical component contains a chemical subject to Proposition 65, you should have it tested by a reputable laboratory. Should you discover one or more pertinent chemicals, a knowledgeable label printer can help you ensure the text and formatting of your warning label is correct.

FCC Mark

The U.S. Federal Communications Commission (FCC) requires a mark of compliance on all devices that emit certain radio frequencies, indicating that the device does not electromagnetically interfere with the operation of other devices.

The FCC compliance mark (below) certifies to consumers that an electronic product is compliant with all applicable FCC regulations concerning electromagnetic interference. The FCC compliance mark should either be permanently affixed on the product, or the manual – assuming the product itself is too small for the FCC mark.

Consult FCC guidelines for more information on which products must carry the FCC mark, how and where the mark should appear, and how to test an electronic product for compliance with FCC regulations.

The compliance experts at the Label Printer can help you determine whether an FCC label is required for your product and the best location for affixing an FCC label.

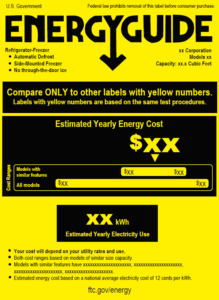

EnergyGuide Labeling

The U.S. Department of Energy’s Appliance Standards Program requires that all major home appliances sold in the United States undergo standardized testing to establish their energy use and efficiency. Appliance manufacturers must then affix a bright yellow EnergyGuide label to their appliances listing:

- The amount of energy the appliance consumes.

- How the appliance’s energy use compares to similar products.

- Approximately how much it costs annually to operate the appliance.

EnergyGuide Labeling regulations apply to clothes washers, refrigerators, freezers, televisions, water heaters, dishwashers, room air conditioners, central air conditioners, furnaces, boilers, heat pumps, and pool heaters.

The U.S. Federal Trade Commission (FTC) provides EnergyGuide label templates (saved as Adobe Illustrator files) on its website. Here is a sample EnergyGuide label for freezers and refrigerators:

Energy Star Labeling

Products that demonstrate exceptional levels of energy efficiency can earn the right to display an Energy Star label. The U.S. Environmental Protection Agency (EPA) determines the qualifications for Energy Star labeling in each product category.

Energy Star is not so much a regulatory requirement as it is a branding opportunity. In its Energy Star Brand Book, the EPA says, “Behind each blue label is a product, building, or home that is independently certified to use less energy and cause fewer of the emissions that contribute to climate change.”

Review the Energy Star branding guidelines with your label printer to ensure your Energy Star label meets color, legibility, and design requirements. (For example, the EPA says that a clear space should surround the mark at all times and its preferred color is 100% cyan.)

Other Compliance Standards for Electronics

Other regulations and standards concerning the labeling of electronics include:

- The Restriction of Hazardous Substances Directive (RoHS), a European Union restriction on 10 (formerly six) hazardous materials in the manufacture of electronic equipment. RoHS compliance is required for the CE mark, which certifies compliance with EU health, safety, and environmental regulations.

- Mercury guidelines, in effect in certain states, which requires the labeling of all products containing added mercury.

- UL marks certify electronic devices or components have met the rigorous safety and reliability standards set by the globally recognized testing firm UL.

Other Factors to Consider for Electrical and Electronics Labeling

Here are a few other special requirements to consider when choosing labels for electrical devices and components:

Static Electricity

Even small levels of static electricity – such as the amount generated peeling a label from its backing – can damage sensitive electrical equipment. The printing process can also imbue labels with a tiny-but-significant static charge, which can then be discharged into devices and components when the labels are applied.

Even small levels of static electricity – such as the amount generated peeling a label from its backing – can damage sensitive electrical equipment. The printing process can also imbue labels with a tiny-but-significant static charge, which can then be discharged into devices and components when the labels are applied.

To prevent damage from static, electrical product manufacturers can choose electrostatic discharge (ESD) labels. This type of label is designed to dissipate an electrical charge over its surface, minimizing the buildup that leads to harmful static discharge.

Recessed Areas and Cutouts

Many electrical devices include recessed areas on their surfaces into which labels must fit snugly. If the labels are too big for the recessed area, they will bubble up around the edges. If the labels are too small, they won’t look right.

At the Label Printers, we can cut your custom label to any size and shape you desire, using precision die-cutting technology to ensure the label meets your specific requirements.

Languages, International Markets and International Regulations

Most of the information on this page is tailored for electronics companies doing business in the United States. Foreign markets may have different regulations concerning labels, especially regarding environmental or health and safety warnings. If you plan to sell your product in unfamiliar markets, be sure to first learn about the local label requirements.

What Kind of Custom Labels Do We Offer for Electronics and Electrical Components?

The Label Printers can meet all of your custom label needs. We’ve worked with electronics manufacturers on a wide variety of projects, including:

Variable Data Labels

Variable data labels use digital printing technology, which relies on data, not plates, to create impressions. There is virtually no limit to the number of data changes the press can process. In one print run, every single label can be different.

Uses for variable data labels include printing individual names, barcodes, addresses, or serial numbers – anything that changes from one label to the next. The flexibility of digital printing can also be used for variable imagery, which can power unique, personalized marketing campaigns.

Security Labels

The market for counterfeit electronics is robust. According to some estimates, as many as one in 10 IT products sold worldwide is fake.

The market for counterfeit electronics is robust. According to some estimates, as many as one in 10 IT products sold worldwide is fake.

Manufacturers whose products are typically targeted for counterfeiting often turn to security labels to help mitigate their risk. Security label features can be overt, incorporating visible—but difficult to replicate—features such as holography and OVDs, color-shifting ink, and serial numbers and codes. They can also be covert, using difficult-to-detect elements such as invisible ink and graphics, microprinting, and forensic features.

These features help customers and retailers identify genuine items and prevent criminals from devaluing your brand.

Tamper-Evident Labels

Tamper-evident labels are another tool for discouraging counterfeiters and gray market sales. A tamper-evident feature is any element of the label that visibly changes when the label is removed or when the item to which it is applied has been opened. The purpose of these features is to alert users to the possibility that someone may have altered an item.

Tamper-evident labels prevent the removal and reuse of a label by people who are unauthorized to do so.

Standardization Labels

Many manufactured products are subject to regulatory standards, with some even requiring official safety and standards certification. Typically, these labels are designed to be difficult to duplicate, as these regulatory bodies have a reputation to uphold and definitely don’t want what appears to be their label on a substandard product.

Regulations, recycling, durability, special requirements…When you consider all the decisions that go into choosing a label for an electronic device or electrical component, it can be difficult to be sure you’re making the right choices. It can be helpful to seek advice from an expert partner that understands the unique circumstances of electrical brands.

To talk about your label needs with an experienced expert today, click here.