Custom Label Buying Guide

Getting the perfect label—the first time and every time

Labels inform. They instruct. They warn us away from danger. They entice us to try new things. For a label to do its job, it needs to not only look good, but also perform.

Many people don’t realize that creating a label is not as simple as choosing a design and printing it on a sticky-backed paper. It has to be done with thought and care. Why? Because the label can be an integral part of the end-user’s experience of a product.

The right label adheres perfectly, lasts as long as you need, and looks exactly the way you want. The wrong label falls off, wears out, or looks terrible — costing you time, money, and reputation.

A lot goes into getting the right label — there are variables you may not know to consider, or that might not be addressed if you rely on the wrong printing service provider.

That’s why we’ve put together this buying guide. By the time you’ve finished reading, you’ll know:

- Factors your printer should consider before making your labels and why those factors matter

- What information your printer may need from you before they can develop a quote

- Questions you’ll get that will immediately let you know you’re dealing with a partner who’s experienced and skilled

Don’t worry — you don’t have to be an expert in labels to get the right label for your needs. This guide simply aims to provide a better understanding of the process, so that when the time comes for you to order, you’ll be 100% confident in your label and in the people making it for you.

Why Your Label Is More Than “Just a Sticker”

All too often, choosing a product label is a last-minute task. The product is almost ready to go, and the job of getting the labels is handed to someone who may understand very few details about the product that the label is actually for.

All too often, choosing a product label is a last-minute task. The product is almost ready to go, and the job of getting the labels is handed to someone who may understand very few details about the product that the label is actually for.

The problem with this process is that the wrong label can make a product look less valuable, or even become less useful. If all you need is a bright orange pricing sticker, go ahead and get that from wherever you find the lowest price. But, for a custom label, a little extra effort goes a long way.

Seinfeld fans might remember the episode when Elaine’s re-gifted Label Baby Junior was used to create shipping labels that fell off in transit, thanks to a failed adhesive. While hilarious in a sitcom, there’s nothing funny about labels coming off your products while in use. Unfortunately, this is something that happens not just on TV, but in real life, to real companies.

Why Your Label Company Should Ask LOTS of Questions

When you first speak with your label printer, you may be surprised (or even a little frustrated) by how many questions they ask. But your label company isn’t trying to annoy you or waste your time. In fact, when your label printer asks you a lot of questions, it’s a sign that you’re in good hands.

Questions from your label company mean three things:

- The label company cares about your business and wants to help you get the best custom labels at the most reasonable price for your needs.

- The label company understands the many considerations that can go into choosing the right label, from regulatory requirements to branding.

- The label company has a wide variety of options regarding processes, equipment, and expertise to create the ideal label for your application. Remember: If your label printer’s choices are limited, yours will be, too.

Your label company’s questions are designed to help you avoid label disasters, ultimately saving you on time and on headaches.

Label disasters? The term may sound dramatic, but results like this can be devastating:

Label disasters? The term may sound dramatic, but results like this can be devastating:

- Your label peeling or falling off because it wasn’t designed for its typical use environment. This can make your product look cheap or flimsy in the eyes of consumers.

- Your label becoming damaged or marred over time because it’s not designed for rough handling, moisture, hot or cold temperatures, or exposure to harsh solvents. This can cause critical information — such as safety warnings — to become unreadable.

- Your label failing to meet government labeling requirements (such as FDA regulations), exposing your company to legal and financial risk.

- Your label lifting or wrinkling because it wasn’t designed for the shape of the product container. This can give your brand a sloppy appearance.

- Your brand colors being off because your printer wasn’t equipped to correctly color match. This can cause your loyal customers to overlook your products.

For example, in the food and beverage industry, the right question from your label printer might mean the difference between your labels peeling off after two weeks in a wine cellar or holding tight. In the electronics industry, smart questions can help you avoid paying fines for violating regulations about warning labels. And in the health and personal care business, your label supplier’s insightful questions will help you design a label that stands out on crowded shelves.

Understanding Custom Labels

It’s difficult to make buying decisions about any type of product without first understanding the basics. Before we go deeper into how to choose custom labels, we thought it would be helpful to explain what we mean by custom labels and explain some of the terminology we may use later on in this guide.

What Custom Labels Aren’t

When we talk about custom labels, we’re not describing a one-size-fits-all solution. Custom labels aren’t stickers designed to be applied to any surface the end-user chooses. Custom labels are, as their name implies, custom-built for a specific product and brand.

Custom labels also aren’t expensive (or at least they don’t have to be). With close collaboration between your brand and your printer, your custom label can be designed to meet both your product requirements and your budget.

What Custom Labels Are

Custom labels can take almost any form you can envision. Custom labels are built by your label company, with your input, to meet your needs and help your brand stand out. Everything about a label can be customized to achieve these goals: size, shape, material, design, adhesives, and so on.

Common Custom Label Terms

You don’t need to know anything about custom labels to have a productive conversation with a custom label company. The company representative will explain to you everything you need to know. But it never hurts to be familiar with a few of the terms you might hear.

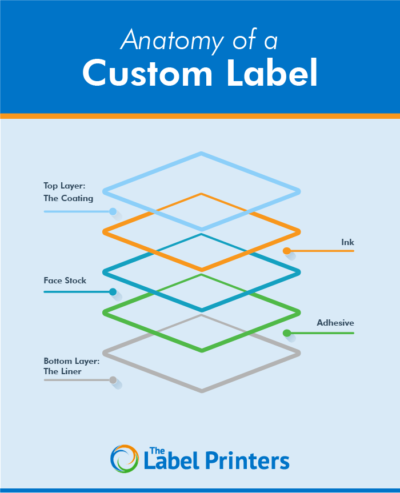

Coating: A topcoat protects your label from the elements while also giving it an attractive choice of finishes. Options include varnish (a liquid coating) and laminate (a transparent film).

Ink: Ink is a pigment or dye dissolved or suspended in a solvent. Many inks also contain additives such as waxes, drying agents, or other substances to create desired special effects (such as with metallic inks).

Face stock: The surface in a label stock construction onto which the image is to be printed. A wide variety of paper, film, fabric, and foil materials are suitable for use as pressure sensitive label face stock.

Adhesive: The sticky substance applied to the back side of the face stock which creates the bond between your label and your product.

Liner: A liner is the material that carries a label through the manufacturing process, storage, and application. Like face stock, liners may be made from paper or film.

Substrate: A surface onto which something is applied. In the label industry, this term is frequently used in reference to the surface to which a label is applied. More generally across the printing industry, the surface onto which an image is imprinted is referred to as a substrate. As a result, this term is used in several ways in discussions of label printing and can sometimes be the source of confusion. The term “Face Stock” provides a useful alternative term to help avoid such confusion.

Check out our helpful Glossary of Label Printing Terms

Before You Order

Before ordering your custom labels, take some time to think about what you want or need your label to accomplish. Your label printer can serve as a sounding board and an expert advisor, but ultimately, your label’s look and message are up to you.

Before ordering your custom labels, take some time to think about what you want or need your label to accomplish. Your label printer can serve as a sounding board and an expert advisor, but ultimately, your label’s look and message are up to you.

If design isn’t your thing, we recommend pairing up with an experienced label designer. There are some incredibly creative and innovative designers out there who specialize in turning your brand’s values and vibe into attractive, one-of-a-kind labels. For inspiration, take a look the our roundups of our favorite wine, beauty product, hot sauce, household product, and overall amazing custom labels.

Some things to think about before speaking with your label designer and your label printer include:

- What audience do you want your label to connect with? What language and tone will resonate with them?

- What do buyers expect from your brand?

- What role will your label play throughout your product’s entire lifecycle, not just in stores but also in your customers’ homes and in landfills or the recycling process?

Inside the Ordering Process

Your label company will ask you the following questions when you order a new custom label:

- Application surface: To what surface will the label be applied?

- Exposure to elements: In what environments will the label need to exist?

- Purpose of the label: What does the label need to do?

- Appearance: What should the label look like?

- Application method: How will the label be applied?

Your answers to each of these questions will help your label supplier determine the combination of adhesive, materials, ink and more that will produce a label that does everything you need, within the budget and timeframe you have.

Let’s take a closer look.

1. Purpose

Labels aren’t just there to look pretty; they have a job to do. What is your label’s job? It may seem like an obvious question, but to build the best label for your needs, your label company will need to know your label’s purpose.

Labels aren’t just there to look pretty; they have a job to do. What is your label’s job? It may seem like an obvious question, but to build the best label for your needs, your label company will need to know your label’s purpose.

Purpose determines a great deal about your label. Will you need to include regulatory information? Are you trying to attract customer attention in a competitive market? Maybe you just need a quick and cheap shipping label for a cardboard box.

All these factors will dictate the right size and shape for your custom label, the composition of materials, the adhesives you use, and so on.

Here are a few examples from different industries of the various roles labels can play:

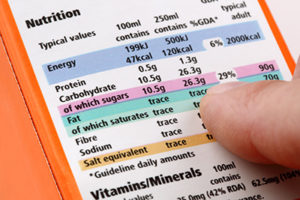

- In the food and beverage industry, labels are important branding elements. They attract consumers by appealing to their sense of identity. Food and beverage labels also inform consumers about ingredients, nutritional content, and cooking and storage instructions.

- In the health and personal care field, labels speak to consumers who are conscious about what they put in or on their bodies. They offer use instructions, warn against misuse, and provide the details required by regulatory bodies.

- In electronics, as well as industrial and automotive fields, labels are used to warn against shock and other dangers. They also provide operating instructions as well as instructions for safe disposal or recycling.

Brand Protection

One purpose labels can serve in nearly every industry is brand protection. Counterfeiting and unauthorized sales are on the rise in fields as diverse as consumer electronics, pharmaceuticals, and fashion, thanks, in part, to flourishing online marketplaces. Brand protection can help you fight back, reclaiming your brand, and your reputation, from the wrongdoers.

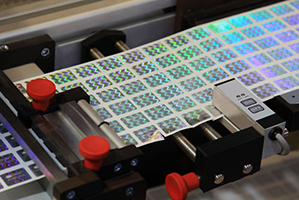

Custom labels can aid with your brand protection strategy, deploying the latest technology to thwart copiers, detect product tampering, and track your merchandise through the supply chain.

Label-based brand protection solutions include:

- Overt security features that cannot be replicated without specialized equipment, such as holography and color-shifting ink.

- Covert security features that help retailers, authorities, and customers determine the authenticity of a product. These include invisible ink, microprinting, and forensic product markers.

- Track-and-trace technology, which allows brands to monitor their supply chains using scannable labels such as barcodes and RFID.

Quantity

A good label printer will ask you about quantity to offer you both the best pricing and the most efficient process.

As with other bulk products, the more labels you order, the less your unit price per label will be. Much of the cost of a custom label reflects the setup. The same setup used to make 100 labels can often make 1,000, 10,000, or even 1 million.

Quantity can also determine the most efficient setup. That’s why it’s important to communicate the short- and long-term forecasts for your product labels with your label printer. If you do, your printer can use that information to plan the most cost-effective production methods and layout for your needs, both now and in the future.

If your company adheres to a lean philosophy such as Kanban or just-in-time manufacturing, your label company should be able to accommodate you through precise inventory management and close coordination with your operations team.

2. Application Surface

The surface onto which the label will be applied has a significant influence on which adhesives will work and which will not.

The surface onto which the label will be applied has a significant influence on which adhesives will work and which will not.

From a scientific perspective, “stickiness” is not a constant. The chemistry of an adhesive will react differently to the chemistry of different surfaces. For example, an adhesive that sticks mercilessly to a porous surface (such as paper or cardboard) may slide right off a non-porous plastic bottle. Environmental factors, such as heat and humidity, play a role, as well.

Another factor to consider is whether or not you want your label to be removable. And if so, how and when? If you’ve ever peeled the label off a drinking glass only to have a sticky residue left behind, you know how frustrating it can be when an adhesive bond is too strong.

These are the kind of issues that can be resolved through a conversation with your label company.

3. Exposure to Elements

The environments in which a label will be applied and used can dramatically impact the label’s appearance and performance. Here are some things your printer will need to have in mind:

Heat and Cold

The temperatures to which a label is exposed, whether during application, storage, transport, or end-use, can have a major effect on its performance.

Take, for example, a water bottle label. It may be exposed to filling with warm water, storage in a cool warehouse, then a cold refrigerator or freezer, and then direct sunlight, the hot interior of a car, or a backpack. Not only does the label material need to be able to withstand these changes, so will the adhesive. If temperature exposures are not considered, the label may not last.

Moisture and Chemicals

Moisture can be devastating to a product label. It doesn’t take much water to reduce a paper label to a pulpy mess. We’ve all seen how easily damp paper deteriorates. This is because water dissolves the hydrogen bonds that hold the wood fibers in paper together.

Moisture can be devastating to a product label. It doesn’t take much water to reduce a paper label to a pulpy mess. We’ve all seen how easily damp paper deteriorates. This is because water dissolves the hydrogen bonds that hold the wood fibers in paper together.

But the effect of moisture on a label goes beyond the label material. Some adhesives perform poorly in damp conditions. Water-based inks will drip and smudge when exposed to moisture.

It doesn’t take full immersion for water to do its worst. For example, let’s say your label will be used on a large piece of industrial equipment. Although the label might never be completely immersed in water, it may be rained on or washed (and possibly with an industrial solvent). When this happens, the last thing you want is for the label to slide off or for its printed image to be degraded.

Options for protecting your label from moisture and destructive chemical solvents include:

- Synthetic materials such as polyethylene and polypropylene, which repel water and are more durable than paper.

- Oil-based inks.

- Protective varnish or a transparent film laminate.

Light

No matter the purpose of your label, it will be exposed to some form of light. Unless the right inks and materials are selected, prolonged light exposures could wreak havoc on your label. Light also can be your friend, by making elements of your printed image sparkle, shimmer, or otherwise stand out. Some safety labels may need to have reflective elements.

We’ve all seen businesses that have made poor choices with their outdoor signage and have paid the price in peeling, sun-bleached signs that do their brand no favors. In this regard, labels are no different. If a label cannot reasonably survive the environments in which it’s placed, it’s the wrong label.

4. Appearance

You need a label that will perform the way you want. But you also need your label to look a certain way.

You need a label that will perform the way you want. But you also need your label to look a certain way.

However, not all designs are created equal. It’s possible the design you’ve created for your label may have unintended consequences. For example, you might have your heart set on day-glow colors, without considering the additional cost that those colors can bring. Perhaps a different shade that’s still bright will give you the same effect, at a lower cost.

Unless you’re working with an experienced label supplier, you may never know that making a slight tweak to your design could save you a significant amount of time or money. By choosing a partner who knows what questions to ask, you’ll gain insight into how your design impacts the label specifications, so you can end up with exactly the right label, at the right time and at the right price point.

Here are some things your supplier should discuss with you when talking about your label’s appearance:

Color and Design

Knowing what you want the label to look like and knowing how to make that work are two very different things. Your label company should explore options with you to make sure you get the look you desire, even if it means choosing an approach you might not have predicted. Sometimes a specific aesthetic can be achieved through an unexpected combination of printing technique, inks and material in a way that creates a unique look.

For example, gradient effects in metallic inks can present special challenges along with several potential paths. You will benefit from having a knowledgeable guide through choices like those.

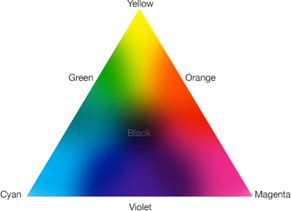

How the color gets put onto the label, whether with spot colors or process printing, can also affect your budget and final results. A spot color is achieved by using an ink premixed to a specific color. Each spot color requires its own print station on a press.

The most common approach to creating process color (four-color process) is printed using a combination of the four standard-color inks: cyan, magenta, yellow, and black. Some printers use extended gamut processes, involving seven (or more) color stations to achieve a greater spectrum of colors than can be achieved with four-color process.

Label Size and Shape

The size and shape of your label may seem like basic questions to answer. However, an experienced label supplier will likely ask some follow-up questions to make sure you get what you need, while still finding ways to ease your budget.

Artwork Requirements

Certain image file types and formats will transfer more directly from design to label than others. To ensure your label design and colors are replicated with the utmost fidelity, follow all of your label printer’s requirements for submitting artwork.

For reference, here are The Label Printers’ guidelines:

Software you should use

- Adobe Illustrator

- Adobe Photoshop

- Adobe InDesign

File formats we can accept

- AI, PSD, TIFF, JPG*, INDD, QXD, PDF

*JPGs should be compressed as little as possible as it will affect quality. Please note that resaving a jpg as a tiff/eps does not improve quality.

Software you should not use

- Microsoft Word

- Excel

- PowerPoint

- Publisher and similar business software

Tips for best quality

- Provide all of the supporting files (fonts, images, and logos, etc.)

- If fonts cannot be provided, present all text as outlines

- Images should be at least 300 dpi. Higher is better.

- Supply artwork to exact dimensions ordered

- Supply proper 1/16″ bleeds when applicable

5. Application Method

You want labels you can apply as easily and efficiently as possible. But what’s easy and efficient in one scenario might be cumbersome and frustrating in another.

For example, if you’re an auto dealer ordering oil change decals for customer windshields, your technicians may not be equipped to handle a roll of labels in the shop. You probably want those labels finished in sheets or maybe even as single pieces held together in a booklet format. But if you’re an auto parts manufacturer and your label will be applied on the plant floor, rolled labels are likely to be exactly what you need to maximize efficiency in automated application.

When ordering labels, it might be easy to say, “It’s just a sticker” and choose a simple online ordering process that requires only a few mouse clicks.

But, if your label doesn’t work for your product, your brand, or your goals, you’ll have wasted significant time and money.

Back in the first section of this guide, we mentioned label disasters. “Disaster” may seem like a strong word to describe something going wrong with such a small thing as a label. But if this guide has convinced you of anything, it’s that a tiny label can contribute in a big way to your product’s success.

To ensure this success, you should work with an informed and experienced label supplier — who asks you the right questions to make certain you get a label that looks great AND performs beautifully.

While we’ve shared a lot of information here, the good news is you don’t have to make all these decisions alone!

When you call The Label Printers, you’ll speak with a label professional who knows what’s needed to get the complete picture. Once we understand your needs and goals, we’ll be able to create the perfect custom label for the job.